ITC Group

Kolkata, West Bengal

Services

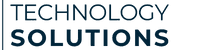

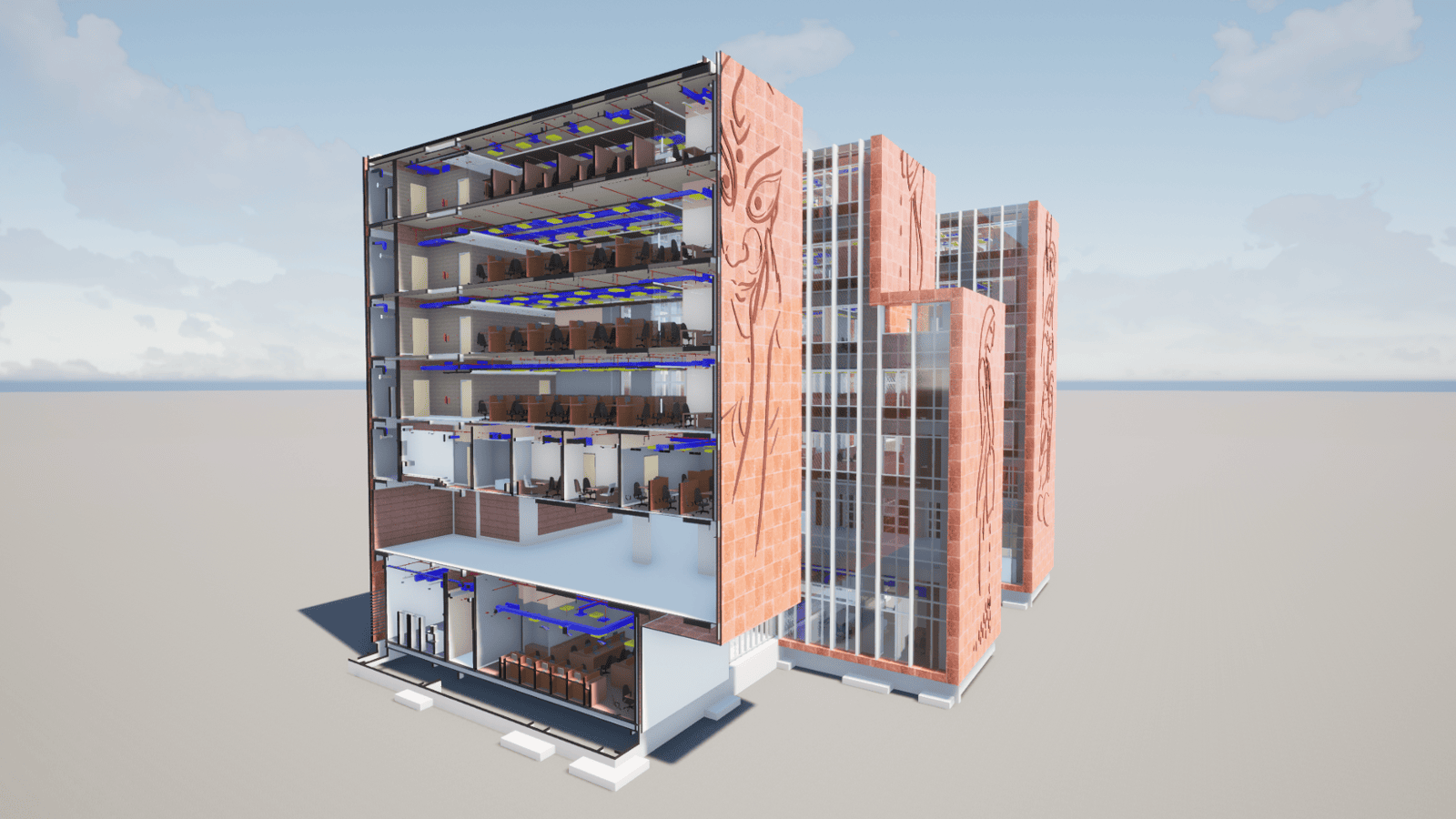

Coordinated BIM Model with Quantity Takeoff

Introduction

The Preconstruction Challenge

Driving Efficiency with 3D Modelling and BIM

Building Information Modelling (BIM) for 5D VDC is enabled by the Architecture, Construction and Construction collection of Autodesk. The set of BIM and CAD tools provided in this collection is supported by a cloud-based common data environment that facilitates project delivery from early-stage design through to construction. 5D VDC uses the collection to create high-quality building and infrastructure designs with conceptual and detailed design tools, and visualisation & simulation tools 5D VDC team has been involved construction consultancy providing virtual design and construction workflows to all stages of construction life cycle. i.e. Design, Pre-Construction to Construction, and has thus saved precious time and money. Initially, the ITC team got 5D VDC onboard for the external landscape development modelling work for the ITC Rajarhat Campus. With a huge prospect of potential advantages of 3D Modelling, they involved the team for pre-construction design and planning for the entire project. This brought in the team’s 3D modelling expertise via Autodesk’s collection, and the project got the required rectification.

“We could track exactly what was stuck where and resolve the issues with the person concerned instead of holding multiple meetings to figure the same. The centralised system also helped track and quantify even minor errors in drawings when they moved from one workflow to the other, and thus helped determine the quality of deliverables from engineering consultants."

– Krishan Saharan | Senior Project Manager, ITC Central Projects Organisation

Centralised Data and Smarter Workflows

Feeling the Impact